The Future of Precision Engineering: Embracing Sustainability and Innovation

- Fahad Mughal

- Oct 15, 2024

- 3 min read

Precision engineering is undergoing a transformative shift, embracing sustainability and innovation to meet the challenges of a rapidly evolving world. As environmental concerns become increasingly pressing, the industry is adapting its practices to reduce its ecological footprint while maintaining the high standards of accuracy and quality that define the field.

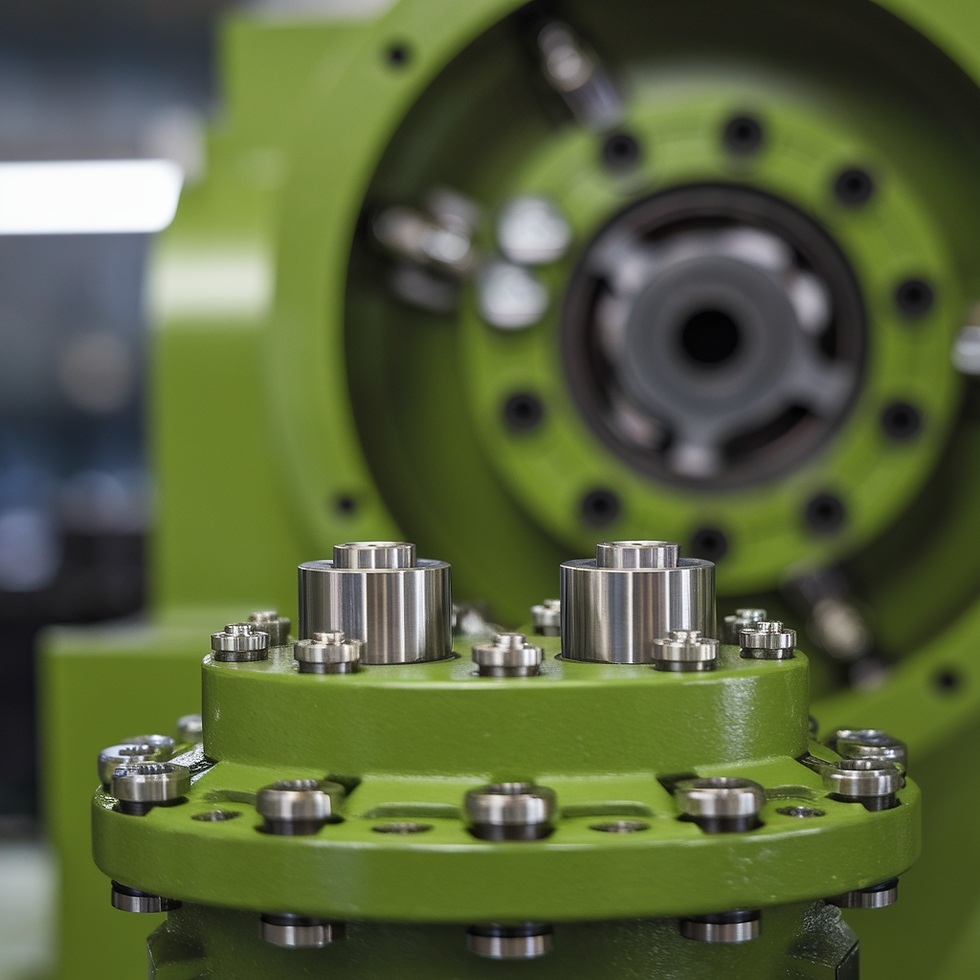

Green Manufacturing Initiatives

Precision engineering companies are at the forefront of adopting sustainable practices in manufacturing. The industry is investing heavily in energy-efficient technologies that significantly reduce power consumption without compromising on precision. Advanced CNC machines equipped with smart features like sleep mode and variable speed drives are becoming the norm, allowing firms to maintain high levels of accuracy while consuming less energy.

Energy Optimization

Beyond machinery, precision engineering firms are optimizing their entire operations to minimize energy usage. Small but impactful changes, such as automatically switching off idle equipment, are creating cumulatively significant energy savings across the manufacturing process. This focus on energy efficiency not only reduces the carbon footprint but also helps control overheads in an era of rising utility costs.

Sustainable Materials and Waste Reduction

The industry is making strides in material sustainability and waste reduction:

Material Innovation: There's a growing shift towards eco-friendly and sustainably sourced raw materials. Recycled materials are being tested and implemented in a wide range of components and products.

Precision Cutting: Advanced machining capabilities are minimizing waste by cutting materials to exact component dimensions, leaving virtually no excess.

Circular Economy Practices: Many companies are implementing "recycle and reuse" strategies to repurpose any remaining waste, creating a more circular manufacturing process.

Precision's Role in Sustainability

Ironically, the very nature of precision engineering contributes to sustainability. By producing components with extreme accuracy, precision engineering reduces material waste and improves the efficiency and longevity of end products. This precision ultimately leads to less resource consumption and lower environmental impact over a product's lifecycle. Design for Sustainability. Precision engineers are increasingly focusing on designing products with lifecycle sustainability in mind. By incorporating principles of Design for Environment (DfE) and Design for Disassembly (DfD), manufacturers are creating products that are easier to recycle, repair, and reuse, minimizing end-of-life waste and maximizing resource recovery.

Innovation in Sustainable Technologies

Precision engineering is playing a crucial role in developing and refining sustainable technologies:

Renewable Energy: The industry is contributing to the advancement of solar cells, wind turbines, and other renewable energy technologies through precise component manufacturing.

Energy Storage: Precision engineering is vital in developing efficient energy storage systems, from advanced batteries to hydro power systems.

Sustainable Transport: The field is instrumental in developing components for electric vehicles, hydrogen fuel cells, and biofuel engines.

Digital Transformation and Sustainability

The integration of digital technologies is further enhancing sustainability efforts in precision engineering:

Data-Driven Optimization: Industry 4.0 technologies and data analytics are being used to optimize processes, minimize errors, and reduce resource wastage.

Digital Twin Simulations: These virtual models help in optimizing product design and manufacturing processes, reducing the need for physical prototypes and minimizing resource use.

Challenges and Future Outlook

While the industry is making significant strides, challenges remain. Balancing the need for extreme precision with sustainable practices can be complex and often requires significant investment. However, as technologies advance and sustainable practices become more ingrained, these challenges are likely to diminish.

Conclusion

The future of precision engineering lies in its ability to continue innovating while prioritizing sustainability. As the world grapples with climate change and resource scarcity, precision engineering will play a crucial role in developing the technologies and products needed for a sustainable future. By embracing this dual focus on innovation and sustainability, the industry is not just adapting to change – it's driving it, shaping a more sustainable and efficient world one precise component at a time.

This is such an insightful post! I can totally relate to how overwhelming academic workloads can become, especially when dealing with multiple business modules. That’s where a reliable business assignment writing service makes a huge difference. Having expert guidance not only saves time but also ensures the work is well-researched and professionally presented. It’s definitely a smart way to balance learning with achieving top grades.

The title The Future of Precision Engineering Embracing Sustainability and Innovation was a cruel joke I was a third year engineering student and my own future felt bleak My online courses were a crushing weight a blur of impossible deadlines and complex projects that left me feeling more and more like a fraud I was a first generation college student and the pressure to succeed was a constant suffocating anxiety I had worked so hard to get here but every day I felt like I was falling further behind The stress was so immense that I felt physically ill In a moment of pure desperation I stumbled upon a website and found a service that promised to have someone who…

There is great promise for the future of precision engineering as the industry gradually opens up fully to sustainability and innovation. With state-of-the-art innovations ranging from AI design to additive manufacturing and green materials, precision engineering becomes not only more efficient but also more cervical. Just like the metamorphoses that different academic disciplines are undergoing to meet the modern needs, like that of law dissertation help in UK, engineering must also adhere to global sustainability goals. Nothing short of an exciting time where it is precision in purpose and innovation in the pact advancing toward a greener future.

The future of precision engineering looks bright as it embraces both sustainability and innovation, driving the industry towards more eco-friendly and efficient practices. As advancements continue, it’s crucial for researchers to stay ahead with in-depth knowledge. If you're working on related projects, a Literature Review service UK can help you gather valuable insights and refine your research.